Vibration analysis is a widely used predictive maintenance technique that enables engineers to evaluate the condition of equipment. In doing so, maintenance personnel can schedule repairs on the equipment during maintenance shutdowns to avoid failures during production runs.

One popular approach that has been deployed to visualize the vibration pattern of a machine involves the use of Operating Deflection Shape (ODS) analysis. In this process, vibration measurements are taken at a number of different locations on a machine using transducers. The data from the transducers is then analyzed by software to create a geometric stick figure model of the structure of the machine and display vibrational patterns.

However, the ODS analysis technique is not without its drawbacks. ODS requires a skilled person to configure mechanical transducers at specific locations on the machine before the data can be acquired. In many cases, the sheer number of collection points can prove problematic.

Having deployed such a system, engineers then need to set up a database to acquire the data from all the collection points and post process the data before a stick figure animation can be rendered. Although this can be achieved through software, it can take hours to complete such an analysis. Also, the data may then need to be further analyzed to determine what is happening physically between each of the points from where the data was acquired.

Vision vibrations

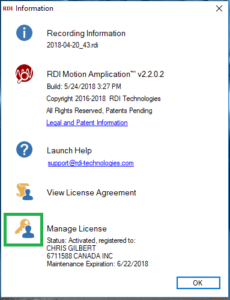

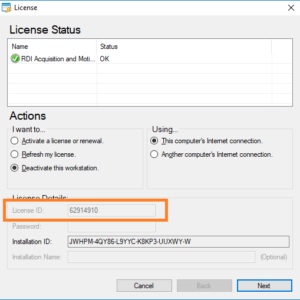

Now, however, engineers at Allied Reliability Group (Charleston, SC, USA; www.alliedreliability.com) have licensed patented technology developed by Dr. Jeff Hay at RDI Technologies (Knoxville, TN, USA; www.rdi-technologies.com) to create a vision-based system called OptiVibe that enables engineers to identify vibrational issues with their equipment with a greater degree of simplicity and in a much shorter period of time (Figure 1).

To read more visit: https://www.vision-systems.com/articles/print/volume-21/issue-4/features/vision-helps-perform-predictive-maintenance.html